What Types of Forklift Attachments Do You Need?

07/07/2020

CITrucks

The manufacturing sector in the United States had a total value of shipments worth $5.4 trillion in 2016. Considering the bulky nature of most of these manufactured goods, moving and handling them can be a real nightmare. That's why most companies utilize the ease and convenience that forklifts introduce in the internal operations of a company.

Do you own a business or warehouse that needs to move bulky goods over short distances? Whether you already own a forklift or are looking to buy a new one, it would help to understand the different types of forklift attachments and their usefulness.

The forks on a forklift is not the only lifting tool you'll ever need. Consider the importance of these other forklift attachments.

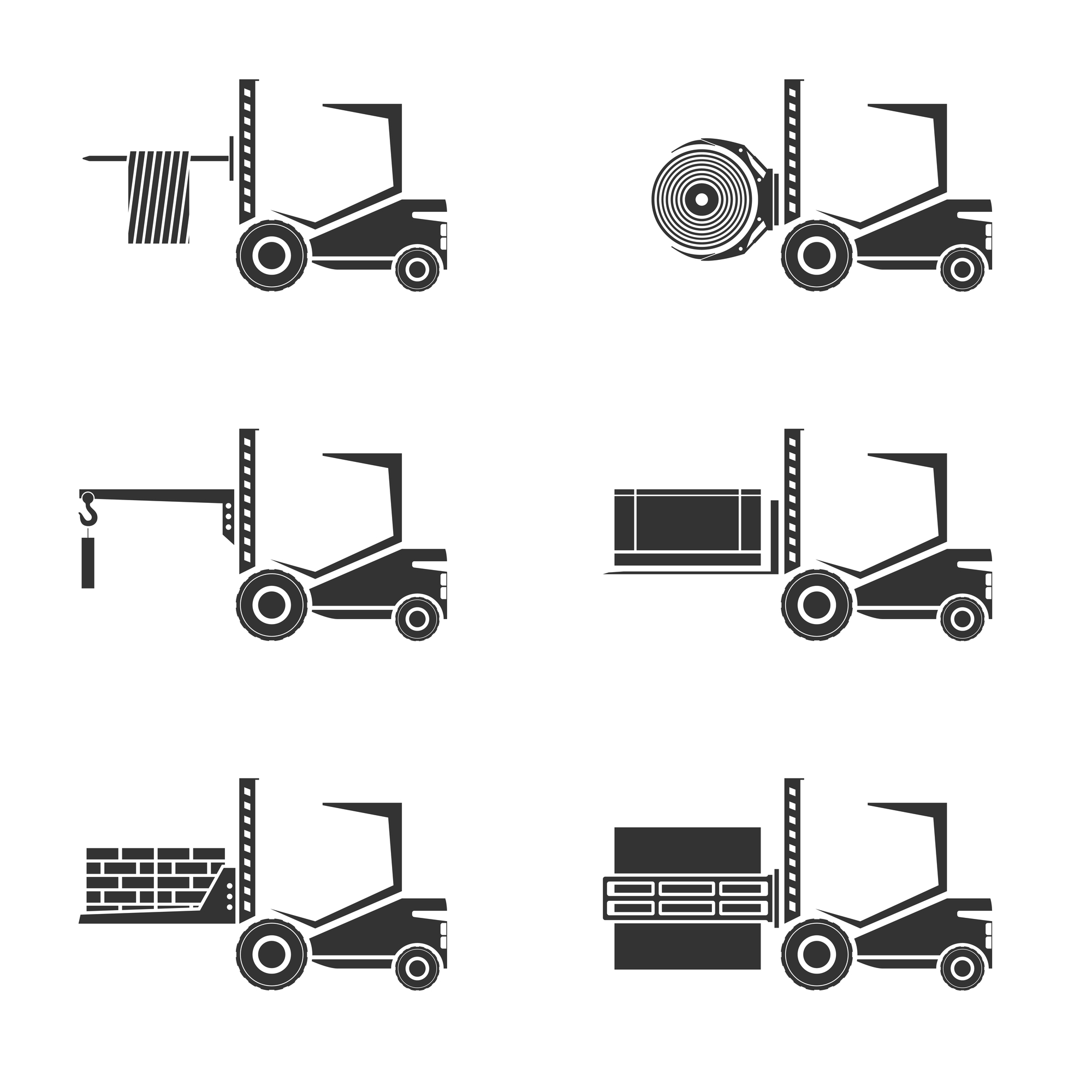

Forklift Attachments

When using powered industrial trucks or forklifts, you might consider a wide range of attachments that aim to enhance the forklift’s functionality. One of the main reasons you might need to consider various attachments is to enhance the truck's versatility. If you hope to improve your forklift's overall functionality, it will help to consider the various parts and their specific benefits.

When choosing a forklift attachment, you should consider stability. Ultimately, you still need to ensure that your powered industrial truck can sustain steadiness in the course of operating heavy loads. Before settling for a forklift attachment, it would also help to consider load capacity. This is especially so for a business with large shipments.

Let’s now assess the types of forklift attachments you might consider.

Fork Positioners

These are among the most common forklift attachments in the market today. The fork positioner allows the forklift to move the forks hydraulically closer together or further apart when handling loads. This approach eliminates the need for manual adjustments in the process of operating the forklift.

Fork positioners use forks to grab the load. However, not all loads are equal sizes. This means that you might need to reposition the forks on more than one instance to ease the process of pickup.

If you’re looking to replace your forks positioners, it will help to consider an option that allows the forks to move in and out simultaneously. With such an attachment, you can pick and drop your loads regardless of the size of the pallets.

Side Shifters

It would help if you had a sturdy side shifter to help the forklift grab the load when in operation. This is an important part of the forklift in the course of operations, given that it helps the operator shift the load from one direction to the next.

It would be best if you had a reliable side shifter to reduce the need for load readjustment each time you move the load.

If you operate a busy warehouse, having a side shifter is important to help you put away or to pick up bulky loads.

Clamps

The clamp is a critical part of a forklift, especially when handling loads that aren’t on a pallet. Do you often handle loads that lack well-defined packaging or that don’t fit on a pallet? You might need an attachment that can grab the load from all the sides.

Forklift Clamps are a critical resource when moving crates, boxes, or foam. You might have a variety of clamps to decide on, depending on the compressor's actual use.

Here are some of the standard forklift clamps to consider.

Carton Clamps

These could either be regular clamps or unique carton clamps with a bigger capacity. Carton clamps help move appliances, such as washers or cased products that may not fit into a pallet. These clamps come with varying side thicknesses to ease the handling of loads that may be stacked together.

Paper Roll Clamps

If you’re handling large paper rolls, you can consider the option of using paper roll clamps. These clamps have circular designs, which make them optimal in grabbing cylindrical loads with ease.

Attachments for Lifting

Do you operate a warehouse that handles loads that don’t have clearance for traditional forks? If yes, the movement of such loads may be challenging considering the complexities in load handling. This necessitates the use of push and pull attachments. These attachments help push or pull the load closer to the forklift and onto the thin forks.

The thin forks attached to the pull and push attachment help lift any load onto the respective destinations with relative ease. Depending on the model, the attachments can handle a wide range of tasks. You only need to pay attention to the dimensions to ensure that they fit your exact needs.

Rotators

Rotators are the other critical attachment that any business handling bulky loads should consider. Depending on the kind of load you handle, moving from one point to the next may require extra caution to enhance safety. You don’t want to end incurring losses caused by damages to the specific loads.

As such, rotator attachments can revolve, dump, or pour loads into specific destinations with relative ease. These attachments can rotate as much as 360 degrees making the management of delicate loads easy and safe. Using rotators makes the process of handing loads faster and eliminates delays.

Consider These Forklift Attachments as Useful Additions to Your Operations

Automation has made load handling easy and effective. If you’re considering purchasing a forklift for your business, you should settle for additional attachments and parts to enhance the forklift’s versatility.

These critical attachments include clamps, rotators, mirrors, side shifters fork shifters, and pull and push attachments. With these parts, your inventory management process will never be the same again. At Carolina Industrial Trucks, we have a wide range of forklift attachments and parts to solve all your load handling needs.

Are you looking for the best forklift maintenance and repair services? Contact us today for immediate assistance.